MOULD SERVICE

Committed to Quality & Management

·Tool Reception and Cleaning

·Tool Inspection

·Tool Fine-tuning

·ECRs

·Graining Management

·Ensure Smooth Production

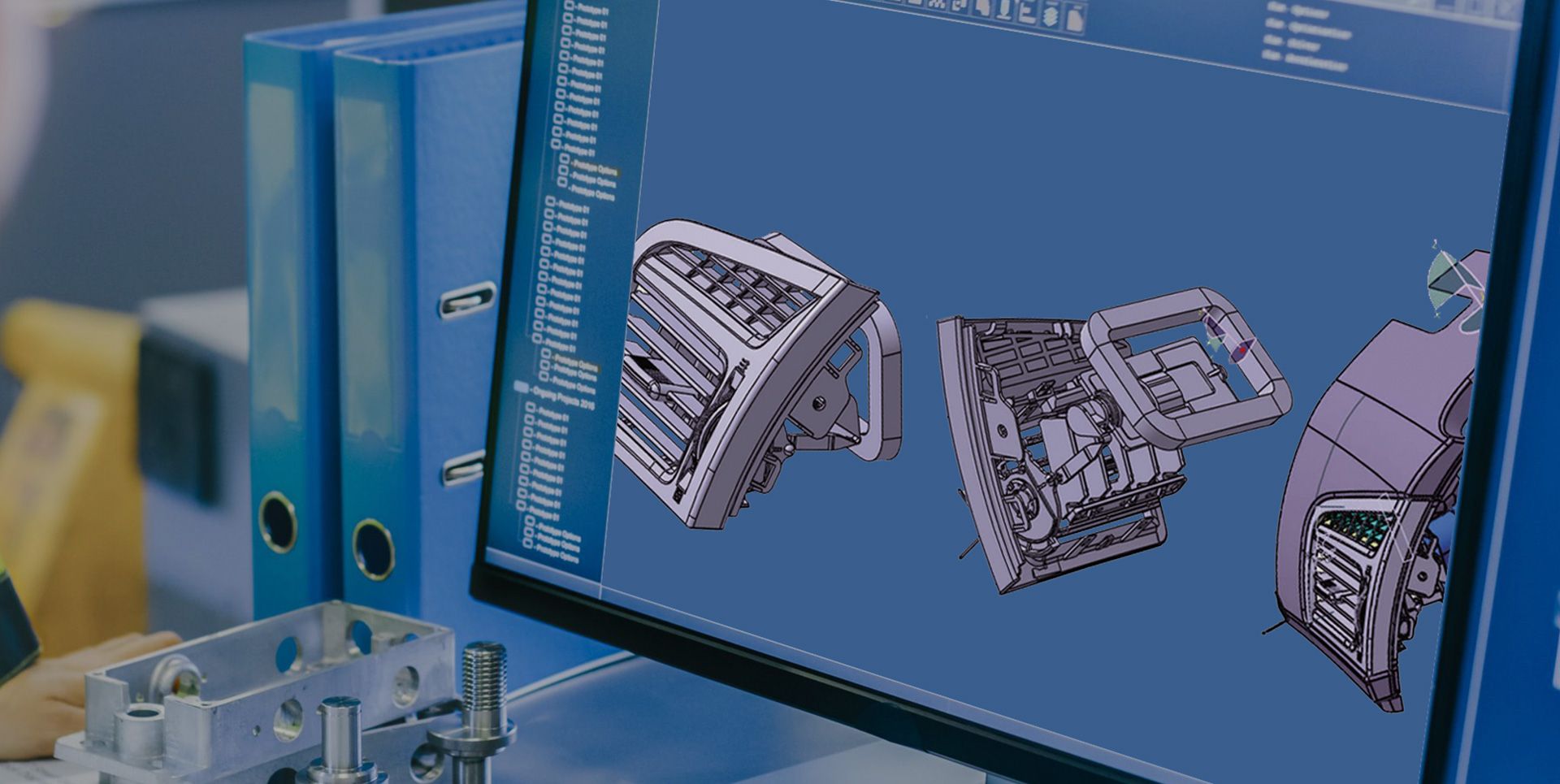

Before we make a quote, we always first make part analysis and mold sketch in system to get proper mold size and structure for reasonable calculation. We can also provide technical support of feasibility analysis at quote stage to help optimize part design, minimize part risks, increase production stability and efficiency.

Our experts are ready to support you with our design for manufacturing expertise from the earliest stages of your product development.

As simple as possible, but as complex as needed. A good mold design meets all your needs and requirements in the most efficient way possible. Inspired by the capabilities of our tool shop, our world-class engineering department has the brains and capability to find innovative solutions that allow for the perfect mold design.

BH is equipped with high-end machines, 30 CNC machines, 18 EDM machines, 9 EDW machines, and in house trial machines, we have professional machining instructions for each process.

From automotive interior, exterior parts to electric, household parts, from package parts to medical parts, from 2K to variotherm technology, we manufacture molds of the highest quality.

BH makes tools from small, precision parts to big parts up to 25 tons by weight and 3200T press.

- Workers: 400

- Injection machines range from 30T to 800T

- 212 injection machines

- 2K machines

- All machines equipped with robot

- Specialized machines for transparent parts

- Assembly lines

- 20% for export, 80% for domestic customers

We manage the project with a whole stable and professional team.

- Full control of technology, quality, lead time

- Package tools project management

- Responsibility of Project Manager

- Direct communication with project team

- Regular conf call meeting

- Follow up from project start-up to final production

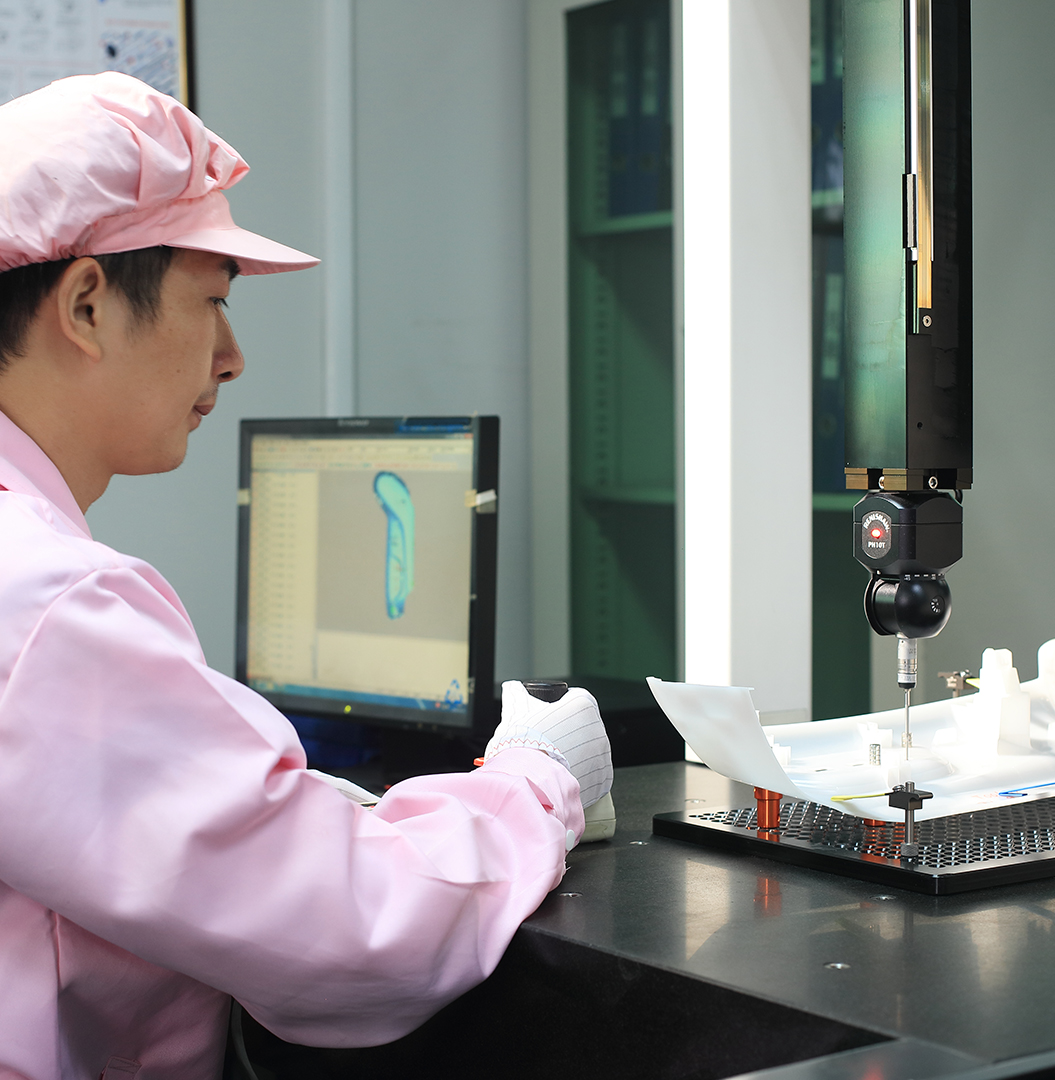

- Mould Steel Hardness Inspection

- Mould Electrodes Inspection

- Mould Core and Cavity Steel Dimension Inspection

- Mould Pre-Assembly Inspection

- Mould Trial Report and Samples Inspection

- Mould Pre-Shipment Final Inspection

- Export Mould Package Inspection

ISO 14001: 2015 TUV certified.

ISO 9001: 2015 TUV certified.

IATF 16949: 2009 TUV certified.

Make moldflow in house.

·Tool Reception and Cleaning

·Tool Inspection

·Tool Fine-tuning

·ECRs

·Graining Management

·Ensure Smooth Production